PDC Cutter

PDC cutters, also known as polycrystalline diamond compact cutters, PDC bits, PDC inserts, is a kind of super hard material. The PDC cutters consist of a polycrystalline diamond layer and tungsten carbide substrate, which are sintered under ultra-high pressure and ultra-high temperature. In short, we say it's HTHP Press. The PDC bits are used for geothermal drilling, water well drilling, and directional drilling.

Drill Bit Nozzles are used for PDC drill bits. There are two main types of the drill bit carbide nozzles for the drill bits. One is with thread, and the other is without thread. Carbide nozzles without thread are mainly used on the roller bit, and carbide nozzles with thread are applied mostly on the PDC drill bit.

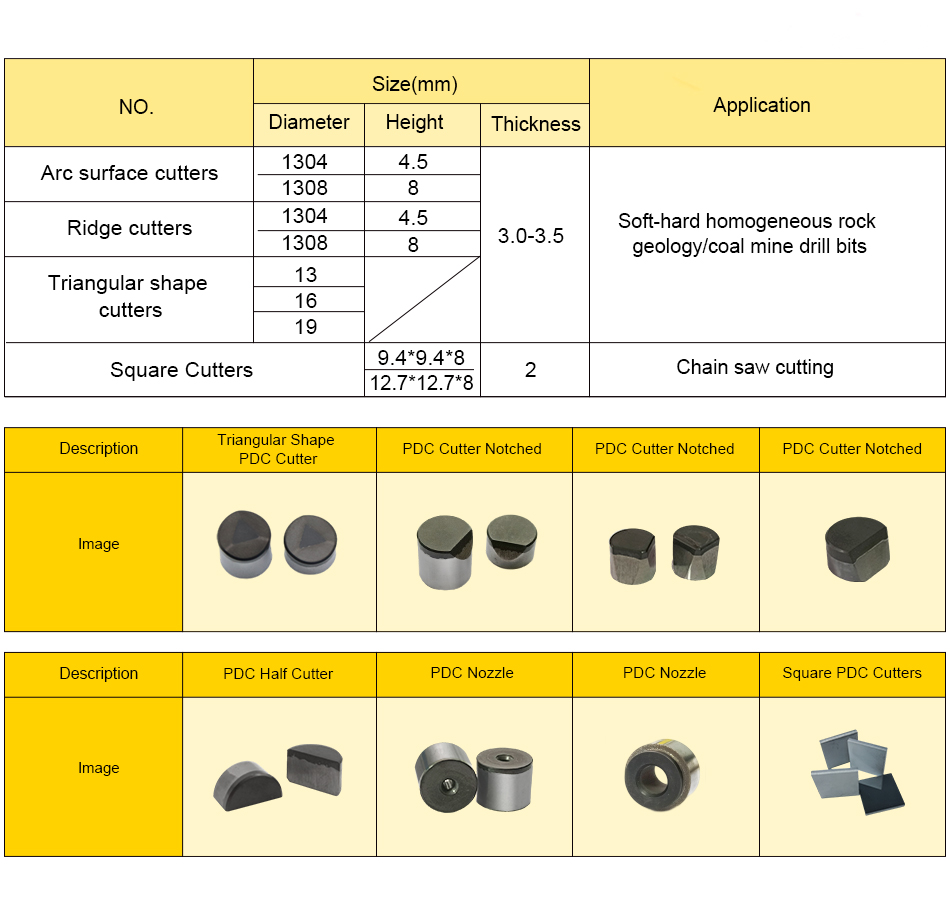

Specialized in PDC cutters, we manufacture PDC cutters in various sizes and shapes, including flat PDC buttons, parabolic PDC cutters, conical PDC cutters, dome PDC cutters, and irregular PDC cutters.

PDC Cutter:

Main Advantages

• High density (low porosity)

• High compositional & structural homogeneity

• Excellent bonding between diamond particles

• High wear resistance

• High impact resistance

• High thermal stability

• Optimized interface between diamond and tungsten-carbide layers for excellent binding

The working life of the PDC cutters is increased by more than 6 times

The production efficiency is increased by more than 20%.

Make the target for one-time completed drilling possible

Reduce the frequency of replacement of drilling bits and the labor intensity of workers.

Sizes of Dome PDC Cutters

Model No. | Diameter | Total Height | Radius | Diamond Height | Grade |

DC110170 | 11.00 | 17.0 | 5.59 | 4.60 | Oil drilling |

DC121170 | 12.07 | 17.0 | 6.76 | 3.65 | Oil drilling |

DC131170 | 13.10 | 17.0 | 7.54 | 3.78 | Oil drilling |

DC139200 | 13.90 | 20.0 | 7.54 | 4.62 | Oil drilling |

DC159240 | 15.90 | 24.0 | 8.26 | 5.94 | Oil drilling |

DC191229 | 19.07 | 22.9 | 9.93 | 7.20 | Oil drilling |

Tungsten Carbide Drill Bit Nozzle:

The cemented carbide nozzle is one of the important components of the diamond drill bit, The tungsten carbide drill bit nozzle is applied to flush, cool, and lubricate the tips of the drill bits, the carbide nozzles also can clean stone chips in the well bottom with drilling liquid in the working conditions of high pressure, vibration, sand and slurry impacting during oil and natural gas prospecting. Carbide nozzles also have a hydraulic rock fragmentation effect. A conventional nozzle is cylindrical; it can produce a balanced pressure distribution in the rock surface.

Types of the carbide nozzles

There are two main types of carbide nozzles for the drill bits. One is with thread, and the other is without thread. Carbide nozzles without thread are mainly used on the roller bit, and carbide nozzles with thread are applied mostly on the PDC drill bit. According to different handling tool wrenches, there are 6 types of threaded nozzles for PDC bits:

1. Cross groove thread nozzles

2. Plum blossom-type thread nozzles

3. Outer hexagonal thread nozzles

4. Internal hexagonal thread nozzles

5. Y type (3 slot/grooves) thread nozzles

6. gear wheel drill bit nozzles and press fracturing nozzles.

We can not only produce standard tungsten carbide nozzle, we also be able to produce the customized nozzles according to the drawings or samples.

TAGS: PDC Cutter Manufacturer PDC Insert Manufacturer

Polycrystalline Diamond Compact Cutting Teeth Manufacturer Polycrystalline Diamond Compact Insert Manufacturer

Polycrystalline Diamond Compact Cutter Manufacturer PDC Cutting Teeth Manufacturer

PDC Cutter Factory PDC Insert Factory Polycrystalline Diamond Compact Cutting Teeth Factory

Polycrystalline Diamond Compact Insert Factory Polycrystalline Diamond Compact Cutter Factory

PDC Cutting Teeth Factory PDC Cutter Supplier PDC Insert Supplier

Polycrystalline Diamond Compact Cutting Teeth Supplier Polycrystalline Diamond Compact Insert Supplier

Polycrystalline Diamond Compact Cutter Supplier PDC Cutting Teeth Supplier

PDC cutters Manufacturer

With modern tungsten carbide production lines, advanced spray drying technology diversified forming processes, and automated HIP sintering equipment, ZZbetter provides over 500 tons of tungsten carbide products for customers at home and abroad every year. Facing the complex and ever-changing needs of the industry, we always strive to offer comprehensive and high-precision processing solutions to satisfy our customers.

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China. 412000

Phone:+86 18173392980

Tel:0086-731-28705418

Fax:0086-731-22286227 28510897

Email:zzbt@zzbetter.com

Whatsapp/Wechat:+86 18173392980