PDC TC TSP Bearings

PDC (Polycrystalline Diamond Compact), TC (Tungsten Carbide), and TSP (Thermally Stable Polycrystalline) bearings are high-performance components designed for extreme wear resistance and durability in demanding industrial applications. These advanced bearings are widely used in downhole drilling tools, precision machinery, and high-load rotating equipment where superior hardness, thermal stability, and abrasion resistance are critical.

PDC TC TSP bearings combine the exceptional wear resistance of polycrystalline diamond with the toughness of tungsten carbide, making them ideal for harsh environments such as oil and gas drilling, mining, and heavy industrial machinery. They are specifically engineered to withstand high axial and radial loads, extreme pressures, and corrosive conditions while maintaining smooth operation and extended service life.

We are a PDC TC TSP Bearing Manufacturer in China.

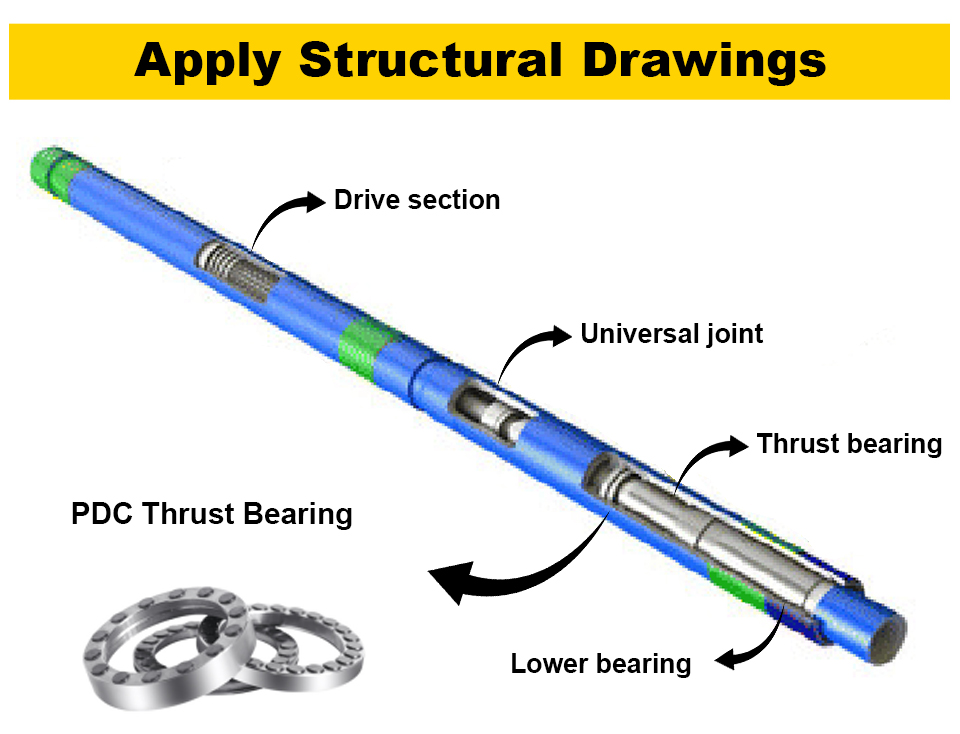

Thrust Bearings

PDC thrust bearings are specialized mechanical components designed to support axial loads in various applications. PDC stands for Polycrystalline Diamond Composite, a material known for its exceptional hardness and wear resistance. These bearings are often used in industries such as oil and gas, mining, and heavy machinery, where they can withstand extreme conditions of pressure and temperature.

The primary function of PCD thrust bearings is to reduce friction and improve machinery efficiency. They are engineered to handle high axial forces while maintaining durability and reliability, making them suitable for demanding environments. When selecting PCD thrust bearings, factors such as load capacity, operating conditions, and lubrication methods should be considered to ensure optimal performance for specific applications.

Radial Bearings

Radial Bearings

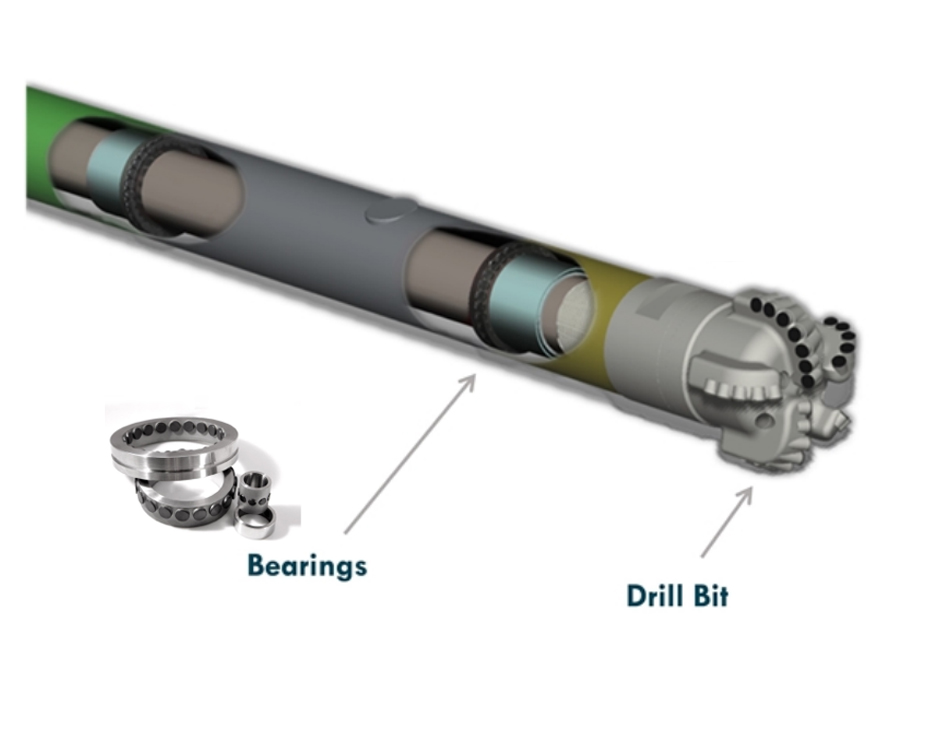

Radial bearings are a type of mechanical bearing that support loads primarily acting perpendicular to the shaft's axis. They allow for rotation or linear movement while minimizing friction between the moving parts. Radial bearings are commonly used in various applications, including motors, engines, and machinery, to help smoothen operational performance by facilitating the movement of rotating components.

PDC Radial bearings

PDC radial bearing is composed of a rotating inner ring and a fixed outer ring, and a series of PDC composite cutters are brazed on the circumferential surface respectively. During operation, the PDC surfaces of the inner and outer rings of the bearing rub against each other. With very low friction, high hardness, high wear resistance, high thermal conductivity, and corrosion resistance, the PCD radial bearing is especially suitable for process fluid sand abrasive particle lubrication, acid-base environment, and other harsh working conditions. The radial bearing can withstand high loads during operation. Due to the low wear rate, the service life of PCD bearings ranges from 1000 hours to years, depending on the application.

TSP Radial bearings

The TSP-radial bearing adopts a high-temperature integrated sintering process with advanced protective measures to improve material oxidation resistance, and the sintering layer shrinks uniformly without defects.

TC Radial bearings

The Tungsten Carbide tile matrix is of special grade for the radial bearings for maximum protection against radial wear. The sintered layer is firmly bonded to the steel body without peeling, and the service can be 300-400 hours.

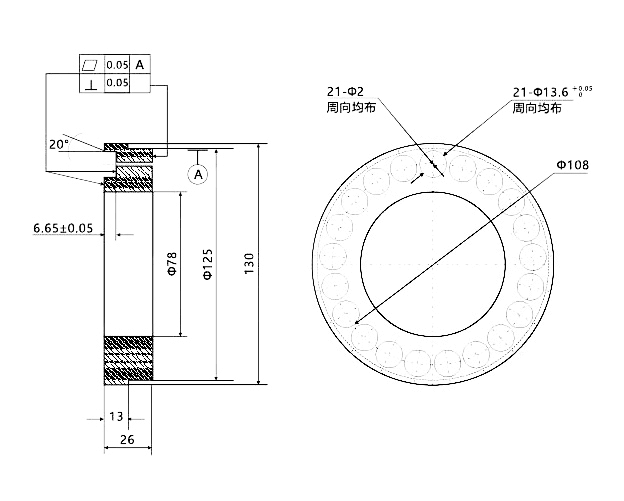

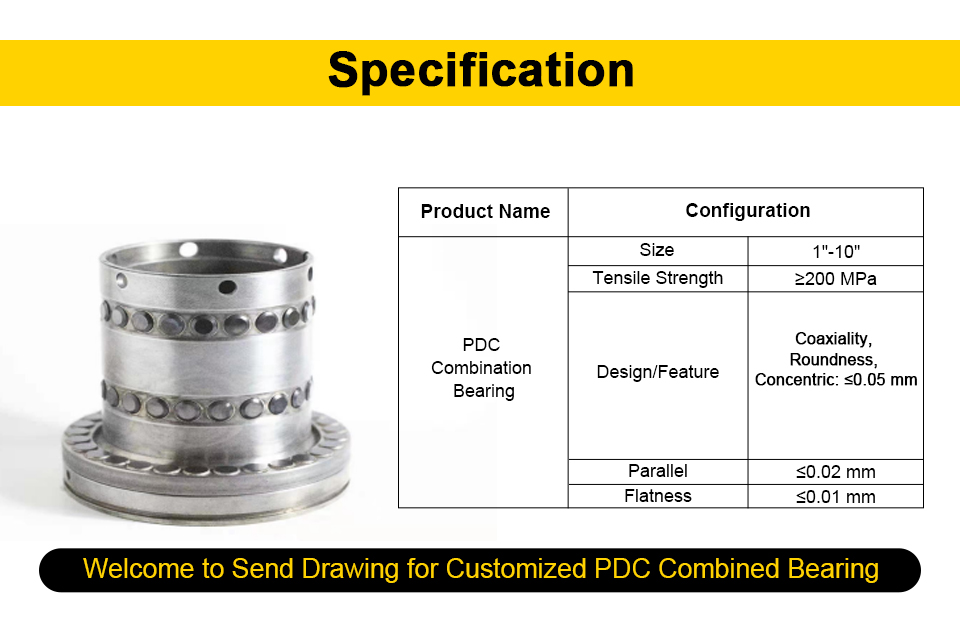

PDC Combined Bearing

The PDC Combined Bearing is a ground-breaking product that combines the power of a standard roller bearing with the accuracy of a precision ball bearing. This revolutionary fusion results in a bearing that is extremely durable and capable of managing enormous loads while maintaining the smooth, low-friction performance required for precise, economical operation.

In some applications, bearings may be required to withstand both thrust and radial loads. PDC combined bearings combine PCD thrust bearings and PCD radial bearings into one bearing unit. The bearing assemblies can be more compactly integrated to meet the requirements of the load and can be adjusted by adjusting the taper angle to meet the requirements of the thrust load and radial load of various applications.

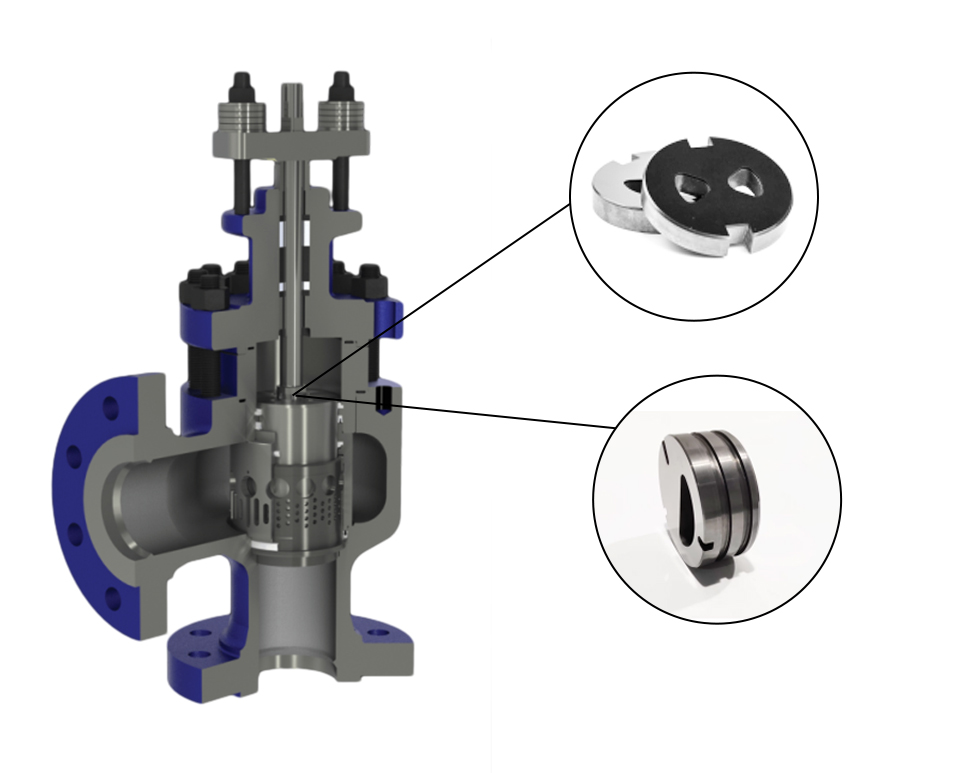

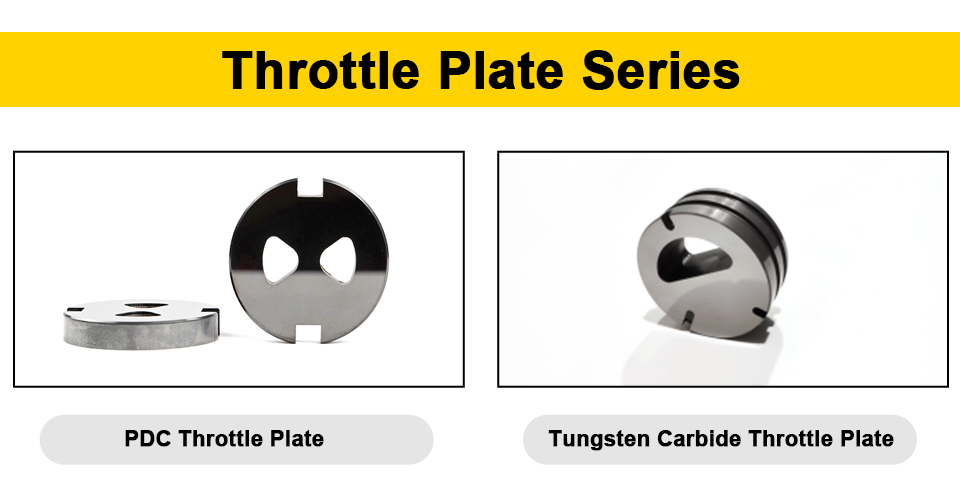

PDC/Tungsten Carbide Throttle Plate

1. PDC Throttle Plate

The PDC Throttle Plate is an advanced throttle control system designed to provide exceptional precision and responsiveness. Engineered with the latest technology, this innovative component seamlessly integrates into a wide range of applications, from industrial equipment to automotive systems.

PDC cutter is especially suitable for high temperatures, containing corrosive chemicals, containing a large number of high abrasive solid particles, and other harsh working conditions. PDC valve made of this material has a long service life, and are stable and reliable. Our company has a unique processing technology, which can be customized according to customer drawings or samples, and the accuracy can reach within 0.005mm of the contact gap between the two surfaces.

2. Tungsten Carbide Throttle Plate

Tungsten Carbide Throttle Plates are a specialized component used in various industrial applications, including the oil and gas industry. Tungsten Carbide is a hard, refractory material composed of tungsten and carbon, known for its exceptional strength, hardness, and wear resistance. The Tungsten Carbide Solid Valve Seat Cutters are manufactured using advanced techniques to create a durable and precise component that can withstand the demanding operating conditions found in industrial environments.

Choke Valves are critical components in oil and gas production, used to regulate the flow of fluids and gases in various stages of the extraction and processing operations. Tungsten Carbide Throttle Valve blocks are commonly employed in Choke Valves due to their distinct advantages, such as high wear resistance, corrosion resistance, and precise flow control.

TAGS:

PDC Bearings Manufacturer China Bearing Manufacturer Radial Bearing Manufacturer Thrust Bearing Manufacturer

PDC Bearings Supplier China Bearing Supplier Radial Bearing Supplier Thrust Bearing Supplier

PDC Bearings Factory China Bearing Factory Radial Bearing Factory Thrust Bearing Factory

With modern tungsten carbide production lines, advanced spray drying technology diversified forming processes, and automated HIP sintering equipment, ZZbetter provides over 500 tons of tungsten carbide products for customers at home and abroad every year. Facing the complex and ever-changing needs of the industry, we always strive to offer comprehensive and high-precision processing solutions to satisfy our customers.

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China. 412000

Phone:+86 18173392980

Tel:0086-731-28705418

Fax:0086-731-22286227 28510897

Email:zzbt@zzbetter.com

Whatsapp/Wechat:+86 18173392980