Tungsten Carbide Blades

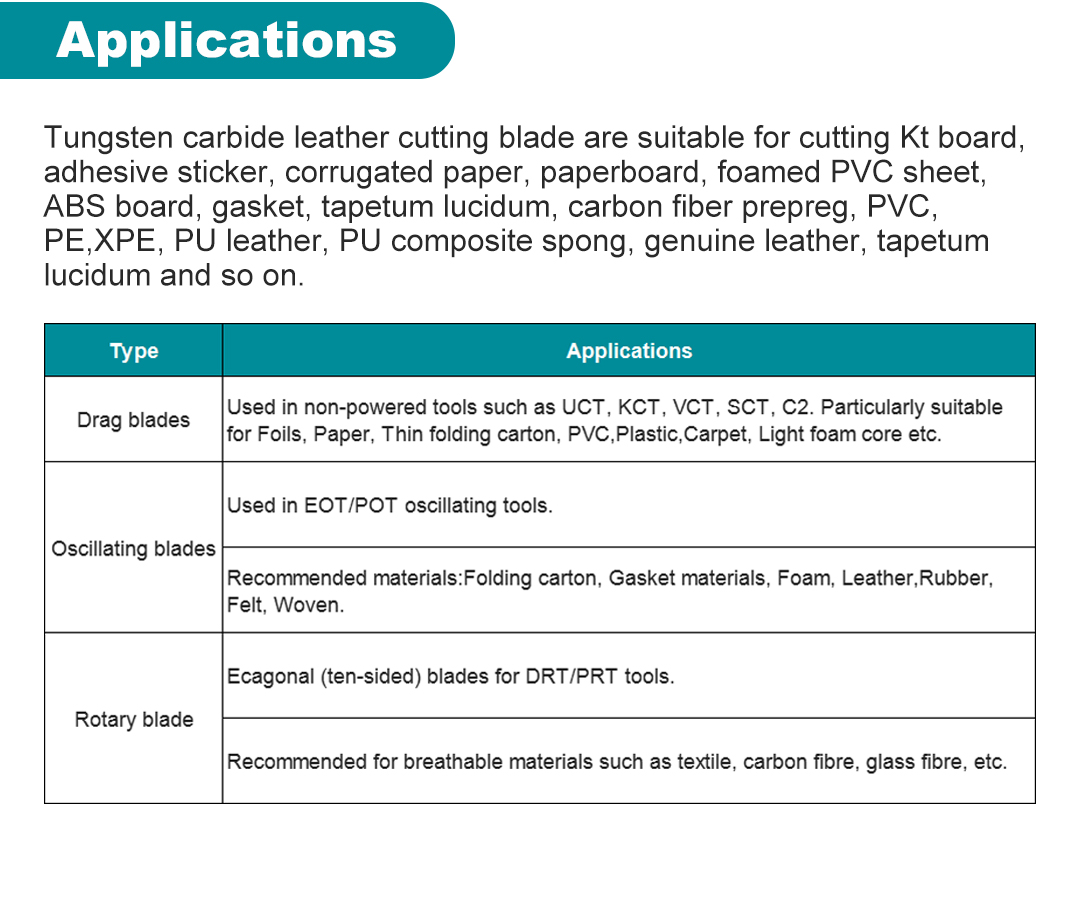

Tungsten carbide discs, also known as tungsten carbide cutting discs or tungsten carbide rotary cutters, are versatile tools used in various industries for cutting, shaping, and machining hard materials. They are made from tungsten carbide, a compound composed of tungsten and carbon, known for its exceptional hardness and durability.

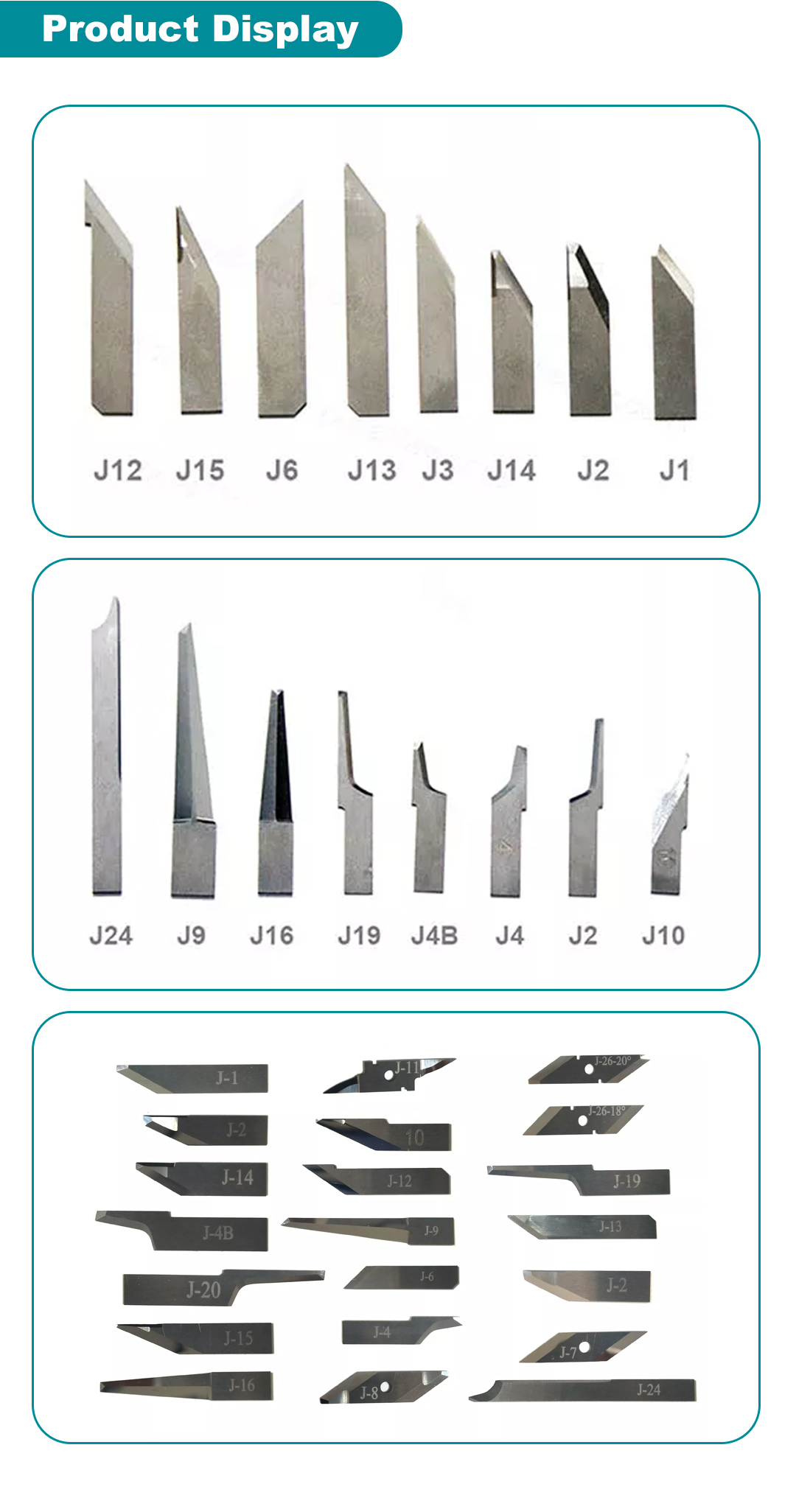

Tungsten carbide leather cutting blades are specialized cutting tools designed specifically for cutting leather materials. They are made from tungsten carbide, a composite material composed of tungsten and carbon known for its exceptional hardness and wear resistance. We also offer blades for the following machines: AOKE, RZCUT, IECHO, JWEI, ATOM, AOL, COMELZ, ESKO KONGSBERG, ECOCAM, ELITRON, MULTICAM, TESEO, ZUND.

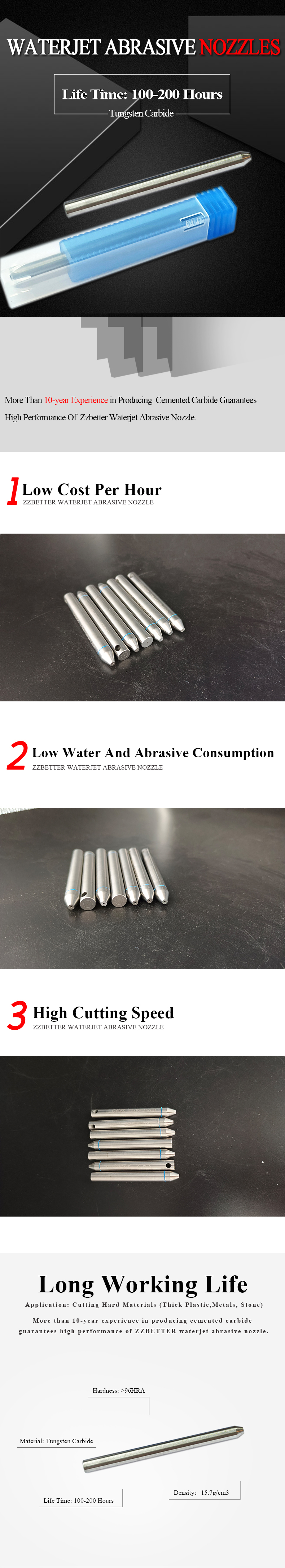

Water Jet Nozzle is used for hard materials like thick plastic, metals, and stone. Superior wear resistance, of course, means a reduction in the number of nozzles purchased over time. But longer life also means nozzles maintain an optimum jet pattern and velocity longer. This allows faster average cutting speeds and significantly reduced system downtime for nozzle re-placement and system calibration. It also means greater dimensional accuracy and the ability to perform longer uninterrupted cuts. These performance enhancements combine to make the entire cutting process more cost-effective.

We are a Carbide Blades Manufacturer in China.

Tungsten carbide discs

product features:

1)Superior Tungsten Carbide For Circuit Board and Electronic Factory

2)Very Sharp Edge and high efficiency

3)Full range of specifications and sizes

4)Various of grades for different requirements

5)Excellent wear resistance, high hardness

6)Advanced production and testing equipment ensure high quality products

7)Every piece of products goes through in-process and final inspection

8)Acceptable for customer's design

Product specification

Tungsten carbide leather cutting blades

Water Jet Nozzle:

Waterjet abrasive cutting nozzle is used for hard materials like thick plastic,metals and stone. Superior wear resistance, of course, means a reduction in the number of nozzles purchased over time. But longer life also means nozzles maintain an optimum jet pattern and velocity longer. This allows faster average cutting speeds and significantly reduced system downtime for nozzle re-placement and system calibration. It also means greater dimensional accuracy and the ability to perform longer, uninterrupted cuts. These performance enhancements combine to make the entire cutting process more cost-effective.

TAGS:

Tungsten Carbide Blade Manufacture Tungsten Carbide Blade Supplier Tungsten Carbide Blade Factory

Tungsten Carbide Disc Manufacture Tungsten Carbide Disc Supplier Tungsten Carbide Disc Factory

Tungsten carbide cutting blade manufacture tungsten carbide cutting blade supplier tungsten carbide cutting blade factory

Tungsten Carbide Circular Blade Manufacture Tungsten Carbide Circular Blade Supplier Tungsten Carbide Circular Blade Factory

Zund Blade Manufacture Zund Blade Supplier Zund Blade Factory

Carbide Blades Manufacturer

With modern tungsten carbide production lines, advanced spray drying technology diversified forming processes, and automated HIP sintering equipment, ZZbetter provides over 500 tons of tungsten carbide products for customers at home and abroad every year. Facing the complex and ever-changing needs of the industry, we always strive to offer comprehensive and high-precision processing solutions to satisfy our customers.

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS:Huanghe North Road, Tianyuan District, Zhuzhou City, Hunan Province, China. 412000

Phone:+86 18173392980

Tel:0086-731-28705418

Fax:0086-731-22286227 28510897

Email:zzbt@zzbetter.com

Whatsapp/Wechat:+86 18173392980